PRODUCTS

HEX BOLT

Hex bolts are characterised by their six-sided hexagonal-shaped head, and they can be either fully threaded or partially threaded. Hex bolts are available in a choice of types, sizes, materials and finishes, offering the flexibility to select the bolt best suited to the particular task or application. Hex bolts are sometimes also known as hex head bolts or hexagon bolts, again due to their distinctive head shape.

RANGE OF HEX BOLTS

Hex bolts are of various categories, based on their sizing, the material or finish used in their manufacture, and whether they are fully or partially threaded.

Hex Bolt Threading

The thread of a hex head bolt, also known as the screw thread, is the helical structure which comprises the main body of the bolt. It uses rotational force to drive the bolt firmly and securely into place, helping to provide easier entrance and exit into the material whilst also providing added grip. Both fully-threaded and partially-threaded hex bolts are available.

Partially-Threaded Hex Bolts

Partially-threaded hex bolts are only threaded from partway down the bolt’s length to the end. An unthreaded shank (also known as grip length) joins the threaded shank and the head. Partially-threaded bolts provide strong levels of resistance. Strain on the unthreaded part of the shank is prevented by the design which ensures that section has no weak spots.

Fully-Threaded Hex Bolts

Fully-threaded hex bolts are threaded from the end of the bolt right up to the head. They are ideal for use in heavy-duty fastening applications and are best suited to installation in pre-threaded holes. Properly installed fully-threaded hex bolts are designed to spread the pressure across the full length of the bolt, providing a greater level of strength than partially-threaded alternatives.

CSK SOCKET

These CKS bots and screws are made out of carbon and austenitic steels and non-ferrous materials in different grades of 6.6, 8.8, 10.9, A2 & A4 Grades.

These types of screws are being used in automotive, aviation, engine parts etc… as the name implies counter sunk it seats in a conical depression hole in flush with the surface.

SOCKET HEAD CAP SCREWS

Socket head cap screws are a kind of machined screws that’s has external threading to be driven with an internal head socket driver (Allen key) these screws head will be driven on a counter bore or on a plain surface depending upon assembly feature. These screws are of safer and reliable in assemblies and as a superior performance when compare to hexagon screws. These screws are preferably made out of alloy steels for higher reliability strength and performance.

TORX

Hex lobular sockets on fasteners ensure a better drive for manual and automated assembly having a lower risk of deterioration with a lower pressure requirement, the lobular can be a Tri-lobular or Penta lobular etc… multi poly lobular

A drive applied on these screws is compatible ensuring more torque and non-slip.

Torx fasteners are high-performance fastening components designed with a unique six-point, star-shaped drive, providing superior grip and torque transfer compared to traditional fasteners. This innovative design reduces the risk of cam-out, a common issue with Phillips and slotted screws, ensuring efficient and secure tightening. Torx fasteners are widely used in industries such as automotive, aerospace, electronics, and machinery, where precision, durability, and tamper resistance are essential.

One of the key advantages of Torx fasteners is their ability to handle higher torque without damaging the fastener head or the tool, making them ideal for high-stress applications. Their star-shaped design allows for even force distribution, reducing wear and extending the lifespan of both the fastener and the tool. Additionally, they offer improved security, as specialized Torx drivers are required to install or remove them, preventing unauthorized tampering in applications like electronic devices, medical equipment, and security systems.

Torx fasteners are available in various materials, including stainless steel, alloy steel, and titanium, providing excellent strength, corrosion resistance, and durability for different environmental conditions. They come in multiple sizes and configurations, such as Torx screws, bolts, and machine screws, ensuring compatibility with diverse applications.

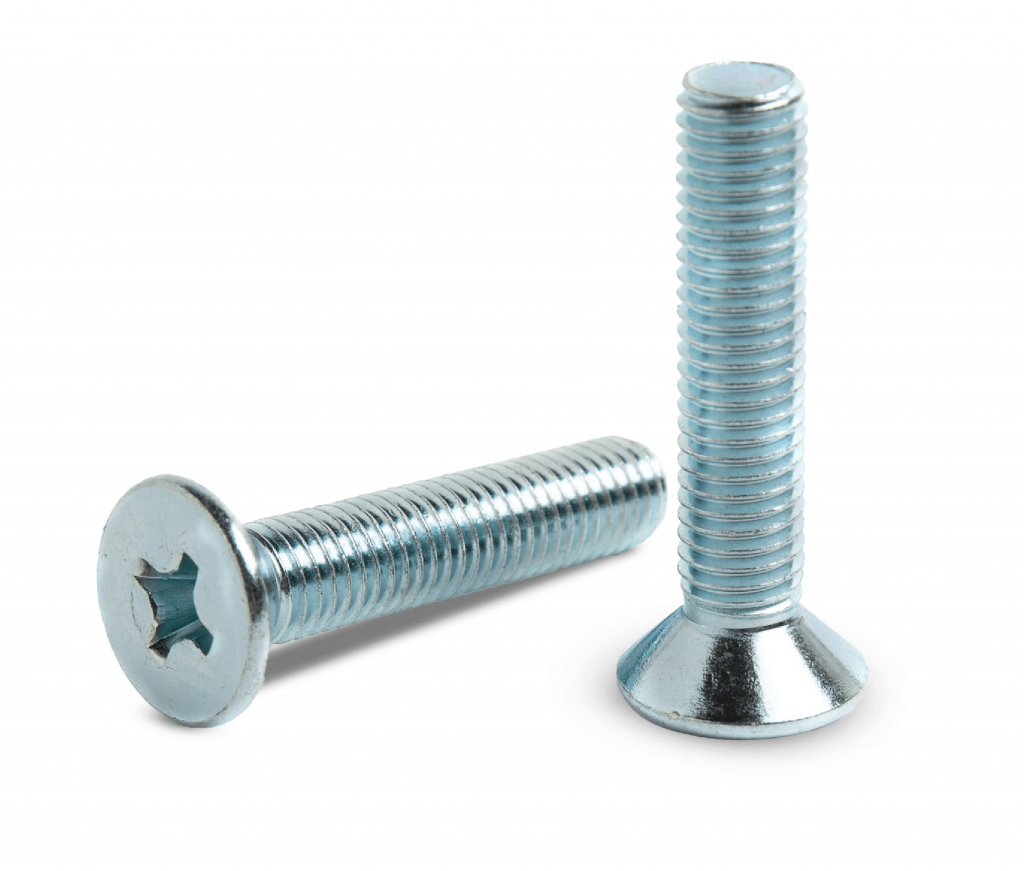

CROSS RECESS SCREW

Is one of the threaded fasteners which can be assembled in a pre-tapped hole or it can cut its own threads as it is driven on a tapped hole. Geometry of the cross recess can vary depending upon the screw driver used. Namely Philips and Pozidriv, H-cross, plus cross etc…

The Double end stud is threaded on both sides of the bolt and should be used when the exact length of thread is known for the application. The stud can be custom-made to fulfil individual necessities. Most recent machines and propelled innovation are utilized in the assembling procedure by our master experts.

The head shape can vary as pan head, round head, counter sunk, hexagonal head etc…

STUD BOLTS

Stud bolt is an assembly of externally threaded fasteners along with internally fasteners this is being used with proper washers in high-pressure, high temperature and applications, via namely piping and pipe line flange connections this is begin

Stud bolt is a fully threaded rod assembled with two nuts with suitable washers.

Stud bolts are essential fasteners widely used in industrial applications that require strong, secure, and high-strength connections. Unlike traditional bolts, stud bolts are threaded on both ends, allowing for a more even distribution of load and stress. They are commonly used in the construction of pipelines, pressure vessels, flanges, and heavy machinery, where high-pressure and high-temperature conditions demand superior fastening solutions. Stud bolts ensure a tight and secure grip, making them ideal for applications in industries such as oil and gas, petrochemical, power generation, and marine engineering.

Manufactured from various materials, including stainless steel, carbon steel, and alloy steel, stud bolts offer excellent strength, durability, and corrosion resistance. They are available in different grades and coatings, such as zinc plating, PTFE, and hot-dip galvanizing, to enhance performance in harsh environments. Depending on the application, stud bolts can be supplied in fully threaded, double-ended, or tap-end configurations, ensuring versatility and adaptability to specific engineering requirements.

One of the key advantages of using stud bolts is their ease of installation and removal, allowing for efficient maintenance and replacement without damaging the connected components. Their ability to withstand extreme loads and vibrations makes them a preferred choice in critical infrastructure projects.

DOUBLE ENDED STUDS AND THROUGH THREADED STUDS

It is a kind of fasteners having threads on both ends with and threaded portion at the middle one end of the thread have been driven metal based and the other one is assembled with the nut. Double Ended Studs has equal-length threads on each end to accommodate a nut and are threaded to a Class 2A fit and the length of stud is measured overall. Both ends have slanting points, but round points may be furnished on either or both ends. Double-end studs are used for flange bolting or other applications where torching from both ends is required or desirable. Double End Threaded Stud is also known as dual threaded rod or double end studs. It is available with equal threads i.e. the same amount of thread at each end and unequal threads i.e. one end has more thread as compared to another. Double End Threaded Rod is suitable for a wide range of applications usually when the rod is fitted into an unthreaded hole, Double Ended Threaded Bolt also known as a stud and it is a relatively long rod that is equally threaded on both ends of a bolt. It is used a wide variety of head designs, as do screws. It is designed to hold with the tool which is used to tighten them. Double Ended Threaded Screw is a kind of fastener that has equal lengths of their shaft threaded on both the ends of the fastener.

U-BOLT

Clamping, pipes, suspension springs etc… it is being used in automotive and industrial applications the shape of the bolt vary like square bend, round bend, V-Bend, as per customer spec wit ethe grades and materials are selected as per the customer spec.

U-bolts are essential fasteners widely used in various industries for securing pipes, tubes, and structural components. Their distinctive “U” shape with threaded ends allows for easy installation using nuts, making them a reliable choice for applications requiring strong and stable support. Commonly used in plumbing, construction, automotive, and marine industries, U-bolts provide a secure grip to prevent movement and ensure structural integrity. In piping systems, they play a crucial role in holding pipes firmly in place, reducing vibrations and minimizing stress. In automotive applications, they are frequently used for securing exhaust systems, suspensions, and chassis components.

Manufactured in different materials such as stainless steel, carbon steel, and galvanized steel, U-bolts offer excellent strength and durability. Their corrosion-resistant properties make them suitable for both indoor and outdoor environments, ensuring longevity in harsh conditions. Available in various sizes, thread configurations, and coatings, they can be customized to meet specific industrial requirements.

RODS

Rods are essential fastening and structural components used across various industries, including construction, manufacturing, automotive, and marine applications. These cylindrical metal bars are designed to provide strength, stability, and support in different mechanical and structural assemblies. Available in a wide range of materials such as stainless steel, carbon steel, aluminium, and brass, rods offer excellent durability, corrosion resistance, and load-bearing capacity, making them suitable for both indoor and outdoor applications.

Rods come in different types, including threaded rods, tie rods, and precision-ground rods, each serving specific purposes. Threaded rods, also known as stud bolts, are fully threaded along their length and are commonly used for anchoring, connecting, and supporting structures in heavy-duty applications. Tie rods are used in structural and mechanical systems to provide stability and resist tension forces. Precision-ground rods are ideal for applications requiring high accuracy and smooth finishes, such as machining and linear motion systems.

The versatility of rods extends to various industries, from construction projects that require reinforcement to mechanical assemblies that demand precise alignment and stability. Their adaptability makes them an essential component in frameworks, machinery, and fastening applications.

CUSTOM DESIGNED SPECIALS

It a specially pre designed fastener suitable to their own use for a customer either in geometry or dimensions & mechanical physical properties for industrial and automotive industries via namely – connecting rod bolts, counter weight bolts, wheel bolts, shafts, in ferrous or non-ferrous metal.

Custom-designed special fasteners are precision-engineered solutions tailored to meet unique application requirements across various industries. Unlike standard fasteners, these specialized components are manufactured to specific dimensions, materials, and performance criteria to ensure optimal functionality in demanding environments. Industries such as aerospace, automotive, defence, construction, and heavy engineering often require custom fasteners to meet stringent safety, strength, and durability standards.

These fasteners can be produced in a wide range of materials, including stainless steel, titanium, high-strength alloys, and corrosion-resistant coatings, depending on the environmental and mechanical demands of the application. Custom-designed special fasteners come in various forms, such as non-standard bolts, screws, studs, washers, and precision-machined components, each tailored for specific load-bearing capacities, temperature resistance, and anti-corrosive properties. Advanced manufacturing techniques, including CNC machining, forging, and coating technologies, ensure high precision, durability, and reliability.

One of the biggest advantages of custom fasteners is their ability to enhance operational efficiency by providing a perfect fit, reducing assembly time, and minimizing wear and tear on components. Whether it’s a high-temperature-resistant bolt for aerospace applications or a specialized locking screw for automotive engineering, custom fasteners play a crucial role in ensuring safety and performance.